TS Group Celebrates a New Chapter: State-of-the-Art Headquarters

We are thrilled to announce that TS Group, incorporating Tapflo UK & Gulf, Sychem Ltd, and Attega Group, is relocating in spring 2026 to brand new headquarters!

In this section you’ll find a wealth of resources including Guides, FAQs, and other informative articles. Find valuable insights and guidance on pump ranges and their applications to further enhance your understanding.

We are thrilled to announce that TS Group, incorporating Tapflo UK & Gulf, Sychem Ltd, and Attega Group, is relocating in spring 2026 to brand new headquarters!

As the UK flooding season approaches, typically running from June through February, Councils, Water Boards, and Emergency Response Planners must have their contingency plans in place before the rain starts falling, because by the time water levels rise, it’s too late to question whether your flood response system can handle...

Supporting infrastructure renewal, overflow reduction and emissions targets for AMP8 As the UK water sector enters AMP8 (2025–2030), Water and Wastewater Companies face an unprecedented opportunity and responsibility to transform how they deliver clean water, manage sewage, and protect the environment. With Ofwat targeting £96 billion in investment, AMP8 shouldn't be seen...

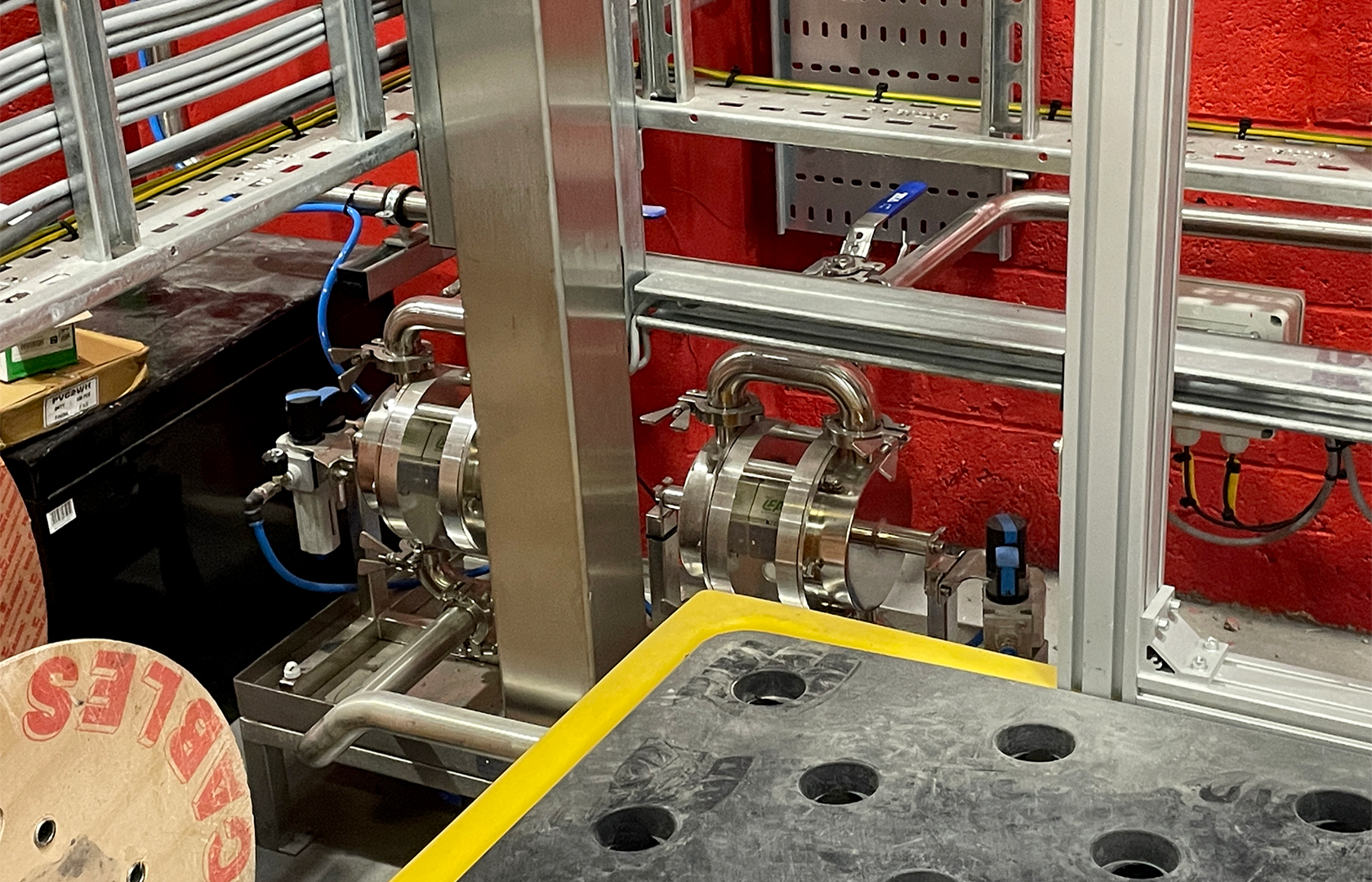

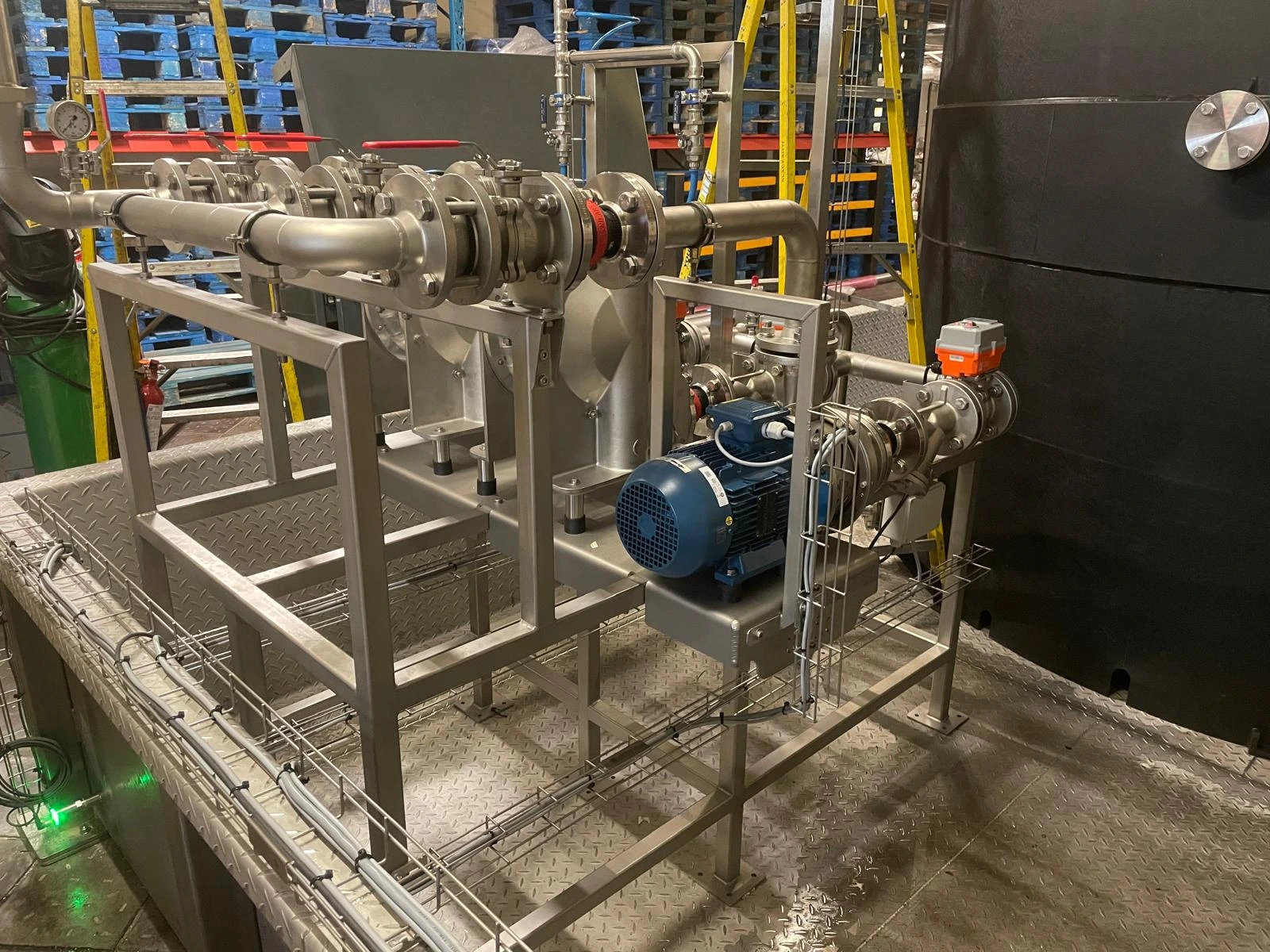

As a leading UK-based manufacturer of process pumps and fully integrated systems, Tapflo UK was approached by a market-leading provider of all trade and construction products for Builders’ Merchants and Trade Professionals. The client required a reliable, safe, and automated system to manage the offloading and distribution of various liquid...

From Brewing and Food Production to Chemical Processing and Water Storage, Stainless Steel Tanks are essential across industries, offering durability, hygiene, and adaptability for various applications. Whether you're considering a standard water tank, a heated process vessel, or a fully customised storage solution, you'll likely have questions about choosing the...

A global food manufacturer needed a more reliable and efficient way to manage wastewater from its production process. Its existing sump system caused frequent pump failures, blockages, and overflows, leading to downtime and operational inefficiencies. To support the company’s sustainability and environmental goals, we delivered a custom-engineered Effluent Management System that...

When it comes to ensuring equipment cleanliness, process efficiency, and regulatory compliance, Clean in Place (CIP) Systems are essential. While commonly associated with hygiene-sensitive sectors like Food & Beverage, and Cosmetics, CIP also plays a crucial role in Chemical Manufacturing, Oil & Gas, and Industrial Production, where contamination control, process...

Stainless Steel Tanks are the backbone of numerous industries, offering unmatched durability, hygiene, and adaptability. From compact 50L vessels to colossal 180,000L storage solutions, these tanks cater to an array of applications, from brewing and food production to chemical processing and water storage. Read on to learn more about Stainless...

Our client is a global leader in advanced, non-nuclear measurement technologies, pioneering precision solutions in dredging, mining, and tunnelling. Their focus on enhancing operational efficiency and safety through advanced process control systems positions them as industry leaders. Collaborating with a client of this calibre required engineering expertise, adaptability, and a...

Optimising Cleaning for Breweries, Food Grade, Cosmetics, and Healthcare Industries Clean in Place (CIP) systems are automated solutions designed for cleaning the internal surfaces of process equipment without dismantling. By eliminating manual cleaning, CIP ensures hygiene, operational efficiency, and regulatory compliance. This guide explores CIP principles, benefits, and applications, with a...

In the ceramics industry, transferring and handling ceramic slurry, also known as slip, poses unique challenges for standard pumping systems. This highly abrasive, viscous material is notorious for causing wear and tear on conventional pump types, leading to frequent downtimes, maintenance issues, and rising costs. Understanding ceramic slurry’s characteristics and...

Customised Process Solutions Engineering That Powers Industries. Innovative Pump Systems and Customised Process Solutions